Menasha converting facilities integrate an ERP system with supplier and customer systems, allowing all involved to cut supply chain costs and streamline operations

|

|

XML-based System Boosts Efficiency For Menasha and Its Trading Partners

|

|

|

By HEATHER DRUGGE

|

Operating more than 20 packaging plants across the U.S., Menasha has embraced the use of technology to improve business operations and customer service. In late 2001, Menasha implemented enterprise business software to streamline internal operations and provide the level of operational consistency needed to maintain its growth pattern.

|

| The need for JIT delivery motivated Maytag to integrate its system with Menasha's. |

|

|

Menasha’s software integrates customer service, order processing, scheduling, shipping, and invoicing. It is comprised of both enterprise resource planning (ERP) and customer relationship management (CRM) systems.

“The ERP system is our new core business platform across our organization and allows us to function more effectively as a national company,” explains Bob Glass, chief information officer for Menasha.

EXTENDING TECHNOLOGY TO CUSTOMERS/SUPPLIERS. Menasha chose VantagePoint Systems, a supplier of software for the packaging industry, as its ERP and CRM systems supplier. The software is currently installed at five of its 24 packaging plants: Mount Pleasant, Tenn.; Brooklyn Park, Minn.; St. Cloud, Minn.; Lakeville, Minn.; and Athens, Ala.The systems will be rolled out to the remaining packaging plants during the next 18 months.

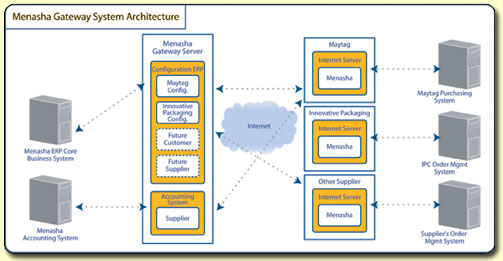

While the executives at Menasha realized that the enterprise software would help the company increase internal efficiencies, they also knew that these benefits could be multiplied by extending the technology to suppliers and customers. Concurrent with the first rollout implementation of the software, developers from VantagePoint used Microsoft’s Visual Studio .Net and message queues (MSMQ), as well as extensible markup language (XML) and extensible style sheet language transformation (XSLT) to engineer a business-to-business integration “gateway” between Menasha, its customer—Maytag—and its supplier—Innovative Packaging.

“As our core business platform, the ERP system is being used to drive a cultural change to adopt common processes across our entire national organization,” says Glass. “The enhancement strategy is to look at how we can expand and improve our services and deliver efficiencies to ourselves and to our customers and partners.”

The .Net environment offers support for XML and Web services, and makes consistent use of industry standards to ensure system longevity. Its framework provides a common language runtime that enables capabilities available in many different programming languages while reducing development efforts. Menasha’s Gateway provides a framework that goes beyond traditional point-to-point integration, allowing it to quickly extend the solution to other trading partners.

FLEXIBLE TECHNICAL ARCHITECTURE. Because Menasha’s Gateway was built using Microsoft Visual Studio, which uses shared communication protocols to remain platform independent, the diverse environments at Menasha (Windows 2000), Maytag (AS400), and Innovative Packaging (Windows) did not present a problem to the implementation team.

The Gateway supports a number of protocols for connecting systems, including file transfer protocols, hypertext transfer protocol (HTTP), simple object access protocol (SOAP), and transmission control protocol over internet protocol (TCP/IP). In this instance, all three Gateway implementations used SOAP, a communications protocol based on XML that is both platform and language independent. SOAP uses HTTP to communicate between disparate applications running on different operating systems.

“SOAP offers a great way to facilitate communications between applications because it is almost universally supported by internet browsers and servers,” explains Glass.

|

| FIGURE 1. The software “Gateway” has simplified operations among Innovative Packaging, Menasha, and Maytag, resulting in improved turnaround, reduced errors, and lower costs. |

|

|

The Gateway can run on an existing single server or can run on multiple servers, depending on the application. At Menasha, it runs on a Windows 2000 platform and communicates with the Oracle-based ERP system. It uses Microsoft SQL Server for message tracking. The Gateway works with any object linking and embedding database (OLEDB) or open database connectivity (ODBC) compliant databases. Components are packaged both as Windows services and as Web services, depending on requirements. Because some components are Web services, they can run locally or distributed across internet boundaries.

The MSMQ framework allows components of the system to distribute across many servers to scale as needed. Using MSMQ to ensure message reliability, the Gateway sends proactive email alerts to system administrators at both organizations. This helps resolve data, hardware, or network issues in a timely manner.

XML is core to the architecture of the overall system and is key to the Gateway’s flexibility. XML allows programmers to describe the data contained within a message, as well as the data itself. This provides a mechanism to move data from one system to another while retaining its original context and making it easier for one system to recognize and actually use the information. The Gateway creates XML routing “envelopes” that provide the context for messages, directing them to the appropriate service for processing. If a message is not intended for a certain service, then that service will automatically forward it to the correct one.

Developers from VantagePoint created a standard set of XML documents used to communicate with Menasha’s ERP system. In addition, they created a standard set of XSLT to translate information from one document format to another to accommodate the disparate formats in place at Innovative. XSLT produces documents of different types for the trading partner's system and can be used to transform most types of documents like flat files, XML, HTML, and EDI. In this case, XSLT was used to ensure that documents from Innovative were recognized by Menasha’s system and vice versa.

For example, Innovative’s order system had some field-format and processing limitations that the team dealt with readily using an XSLT filter to translate data formats from Menasha’s system to Innovative’s. Messages from Menasha (if they contain invalid values) pass through an extra data cleansing process to convert the data format to one compatible with the Zytek system at Innovative. The messages then continue along their normal path for processing.

This illustrates one of the benefits of the .Net framework, which allows processes to run independently. Individual processes communicate with one another using MSMQ, which provides reliable messaging. Also, any Web services can also communicate directly through HTTP/HTTPS. As a result, when a new process or service is required, it can “drop in” between existing processes without affecting existing functionality.

To secure the order information as it travels in packets across the internet, engineers from VantagePoint adopted the Web Services Interoperability Organization’s (www.ws-i.org) security recommendations, which include authentication, privacy, and non-repudiation. Using a combination of digital certificates, digital signatures, and encryption, the Gateway ensures that messages cannot be intercepted or corrupted.

DEMAND CHAIN TECHNOLOGY REDUCES COSTS FOR MAYTAG. Maytag’s central parts warehouse ships millions of parts every year. Unlike its manufacturing business, where it develops just-in-time (JIT) production schedules with suppliers to minimize inventory, Maytag’s parts business is demand driven. As a result, the Maytag parts warehouse was forced to store a lot of inventory.

“Our carton material usage is very fluid,” explains Don Batty, Maytag’s warehouse optimization manager. “We averaged a 42-day supply of corrugated material, consuming about 10% of our warehouse space.”

With space already at a premium at the warehouse and the need to find additional warehouse space to store new products resulting from a recent acquisition, Batty needed to implement a solution that would allow development of a JIT corrugated delivery system.

Since the company had a strong relationship with Menasha, the key was to integrate Menasha’s ERP system with Maytag’s home-grown purchasing system, which managed the warehouse’s internal operations. A Gateway was developed between these systems, automating a once manually-intensive ordering process.

Maytag now enters new packaging material orders into its internal system, which is sent to Menasha. The order is automatically entered into Menasha’s ERP system where it is processed, scheduled, and shipped to Maytag by 7:30 a.m. the next day. The Gateway then sends a closure transaction to the Maytag system and automatically creates an online paperless invoice.

The new system has automated a manual process, helping to save time, increase efficiency, and reduce errors. In addition, the new system has let Maytag develop a JIT system that has resulted in a reduction of inventories, providing much needed space for the new inventory. The advantages of integrating its operations with its packaging supplier include increased order accuracy, improved delivery management and inventory visibility, and improved efficiency and accuracy in invoicing operations. Such advantages have resulted in an overall reduction in transaction costs.

For Menasha, the advantages of implementing the Gateway include the ability to deliver a better level of customer service, resulting in more customer loyalty, competitive edge, improved productivity, and lower transaction costs. The system eliminates the time used to handle faxes and phone calls. The key to its success, according to Glass, is the fact that Menasha’s system is a true extension of Maytag’s internal system.

“Too many companies force all of their customers to use a one-size-fits-all portal,” says Glass. “When you deal with large transaction values and high order frequency in a high-value relationship and have an opportunity to substantially drive costs out of both your business and your customer’s business, it makes sense to become an extension of your customer’s system.”

SUPPLY CHAIN TECHNOLOGY AT INNOVATIVE PACKAGING. Innovative Packaging Corp. is a Milwaukee, Wis.-based sheet feeder and one of Menasha’s key suppliers. Innovative has been in business only five years, but has carved out a niche in the Midwest area by concentrating on small orders that require short turnaround, strong customer service, and quality.

Innovative handles approximately 50 Menasha orders a day, all of which need to be turned around by the following morning at 7:00 a.m. To meet Menasha’s needs, Innovative must turn around product quickly—without error. In addition, Innovative is always searching for ways to reduce transaction costs. The supplier also realized that the best way to accomplish these goals was through technology.

Before the Gateway was extended to Innovative’s operation, all orders between Menasha and Innovative were handled manually. Menasha would write up the order and fax it to Innovative, who would then pull the order from the fax machine, re-key the information into its system, check to make sure the information was keyed in correctly, and then confirm the order with Menasha.

Now that Innovative’s Gateway has been developed, the order procedure is fully automated. Purchase orders are entered into Menasha’s system and sent over the internet as text messages to Innovative’s system. The Gateway automatically transforms and enters the order. It is then verified by the system, and a confirmation that the order can be fulfilled is automatically sent to Menasha.

The Gateway has greatly reduced the amount of time that it takes to enter and process an order between Menasha and its supplier. The process now takes significantly less time, and errors have virtually been eliminated. Innovative is also able to deliver the level of customer service that Menasha has come to expect.

The system has also had an impact on Innovative’s bottom line, enabling the supplier to save money through a reduction in errors and a more efficient ordering process. In a high-volume, low-margin business like the sheet feeding business, automating processes internally and with customers and suppliers can provide a significant competitive edge.

“Pricing pressures have become more intense over the past year,” explains John Lingle, president of Innovative Packaging. “When people buy less, there is less to go around. Everyone is fighting for the same piece of the pie. The integration with Menasha’s ERP system has allowed us to reduce errors and decrease our turnaround from a couple of hours to 20 minutes.”

CHALLENGES WITH TRADING PARTNER SYSTEMS. When creating automated trading partner systems, there are often multiple information technology departments involved. Coordinating these disparate groups can be a real challenge. As a result, some of the biggest challenges the software supplier’s engineering team faced were not technical but procedural.

“Whenever a company automates a business process, the little things that a person will automatically do when processing an order do not always come to the forefront in a requirements assessment,” says Glass. “So, policy and procedures are extremely important when building a system-to-system process.”

However, Menasha’s Gateway provides a framework on which many other trading partners can communicate and emerging Web services can be incorporated. Web services provide a way for organizations to describe their interfaces in enough detail to allow users to build a client application. This description is usually provided in an XML document called a Web Services Description Language (WSDL) document. XML Web services are registered so that potential users can find them easily through public Universal Discovery Description and Integration (UDDI) libraries.

Heather Drugge is president of Go Communications in Vancouver, B.C.

|