Removing splinters from the process

by Pasi Mäkelä

Metso Paper's woodhandling division has been working with Jari Celulose in Brazil to develop a process for debarking eucalyptus logs. After three years of research, the companies have finally come up with a solution

|

Jari Celulose is located on Jari river in the north of Brazil in Pará State |

Metso Paper's wood handling division may be based in Finland, but during the past three years, the supplier has been busy installing a new system in Brazil. In 1999, Jari Celulose decided to invest in a new wood handling plant at its pulp mill on the Jari river in the north of Brazil in Pará State (PPI, October 2001). The main target of Jari's project was to increase production capacity and uptime, as well as to cut the operating costs and to use longer logs. After scrutinizing the competition, the company picked Metso Paper to supply the new wood yard, which is designed for processing 290 m³/hr of eucalyptus. The plant started up in June 2001 and is said to be the first site in the world to successfully debark 6 m long eucalyptus logs in continuous operation throughout the year.

The groundwork for the project began as early as 1996, when a team of experts from Metso Paper traveled to Brazil to participate in eucalyptus production trials at Jari's 305,000 tonne/yr bleached eucalyptus kraft pulp mill. The tests were designed to find out how a log length of 6 m would affect the debarking efficiency for the eucalyptus wood species used in the mill.

The GentleFeed drum infeed system provides high process uptime

with minimum wood loss |

Despite the long log length, the trials produced some good debarking results. The process easily reached a target cleanliness of 1% bark in the chips. On top of that, most of the logs were completely clean. The amount of broken logs was kept reasonably low, which is an impressive result considering that the existing plant was originally designed for processing short logs.

Production trials showed clearly that 6 m long eucalyptus could be effectively debarked without variations from normal eucalyptus line configurations. But it was not all plain sailing for the project leaders. There were still some issues to be taken into account such as log diameter, both minimum and average, and time between harvesting and debarking.

Gently does it

Due to local conditions, the processed wood raw material is fairly small in diameter and contains dust and sand. These factors call for special wood preparation measures to be taken at the mill. In conventional drum infeed systems using chain conveyors, the plant suffered high wood losses with low process uptime and high maintenance. To solve this problem, Metso Paper installed a GentleFeed drum infeed system.

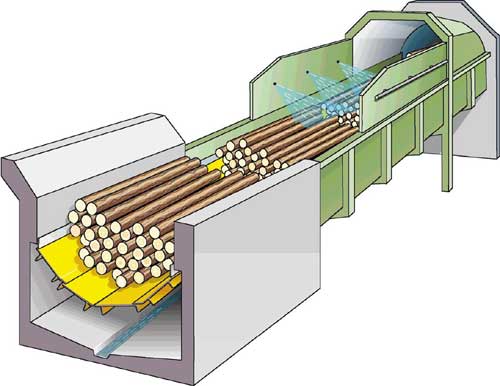

GentleFeed is a horizontal drum infeed system that feeds the logs in bundles into the barking drum. The feeder system avoids the need of a chute, which may cause log breakage. On top of that, with roller-supported conveying elements, there is no need for conveyor chains.

Another feature of the GentleFeed system is that it considerably reduces maintenance due to its non-friction support. The round and smooth bottom of the unit enables the log bundle to start rolling freely at the drum infeed, keeping the logs intact with minimum breakage.

The logs are washed in a washing station to remove sand prior to debarking. Due to the unique design of GentleFeed, there is no point where plugging could take place, which is a common problem with chain conveyors. By avoiding blockages and breakages, the drum infeed system has high process uptime.

Schematic of the GentleFeed with log washing |

Stripping off

Moving along the production line, logs are debarked in Metso's rubber-tire-supported EasyTyre barking drum. Compared with the old drum, the casing, volume and open area are larger, raising the debarking degree and improving bark removal through the slots.

Even though the drum volume and open area have been increased, a large amount of loose bark still exits the drum together with the debarked logs. To combat this, the line between the drum and the chipper was specially designed for separating long lengths of eucalyptus bark. Now that the controls have been tweaked, effective bark removal is achieved with controlled rotation direction and speed of the rolls. As if that is not enough, the rolls are shaped to cause internal log movement during conveying, which results in the removal of loose bark from the log flow.

The EasyTyre barking drum was chosen to rise the degree of debarking and to improve bark removal from the drum |

After the barking drum and secondary log washing stage, the logs are fed into a drop feed Camura GS 15-3000 back discharge heavy duty chipper. Since the startup of the unit, the bark amount in chips after screening at nominal plant capacity has reached an average 0.4%.

Following the chipper, chips are screened with a CSR 1000 gyratory chip screen unit, which is designed to resist corrosion. Other equipment commonly suffers from corrosion problems when screening eucalyptus chips.

Working together

Metso Paper's dealings with Jari do not stop there, either. Jari his investing $416 million at the site over the next 10 year. Metso Paper has already scooped orders for equipment including a new pressurized bleach screening plant for better pulp quality. The pulp producer is able to supply market pulp with a cleanliness as high as 0.5 mm²/m² with the new system.

The contract also included a Metso rebuild of the cutter layboy, as well as modernization of the baling lines for better bale quality.

Pasi Mäkelä is vice president of marketing and sales at Metso Woodhandling based in Finland

|